© BELMONT PLATING WORKS, INC. 2016

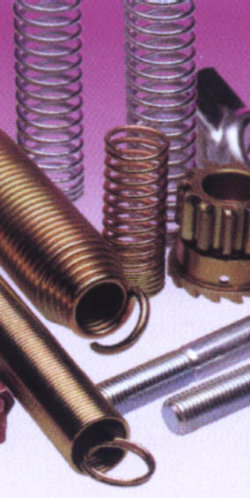

AVAILABLE IN RACK AND BARREL PROCESS

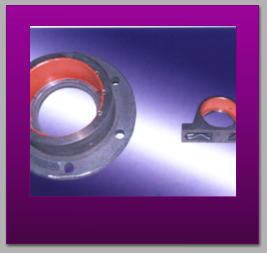

ELECTROLESS NICKEL DESCRIBES THE PLATING OF NICKEL DEPOSITS ONTO A SUBSTRATE BY CHEMICAL REDUCTION. THESE DEPOSITS MAY CONTAIN UP TO 13% PHOSPHORUS BY WEIGHT. UNLIKE ELECTROLYTIC NICKELCOATINGS, ELECTROLESS NICKEL COATINGS ARE PRODUCED ONTO CATALYTIC METALLIC SUBSTRATES WITHOUT ELECTRIC CURRENT APPLIED. BY AVOIDING MANY OF THE PROBLEMS ASSOCIATED WITH ELECTROLYTIC APPLIED COATINGS, THESE DEPOSITS PRODUCE VERY UNIFORM, HARD AND LUBRICOUS COATINGS. THE DEPOSIT UNIFORMITY ALLOWS PLATING OF VARIOUS COATING THICKNESSES ON ANY SECTION OF A PART. GROOVES, SLOTS, BLIND HOLES, THREADS AND EVEN THE INSIDE OF TUBING WILL HAVE THE SAME THICKNESS OF COATING. BELMONT PLATING WORKS, INC. OFFERS IT'S CUSTOMERS TWO OF THE MOST WIDELY USED ELECROLESS NICKELS IN THE INDUSTRY, HIGH PHOSPHORUS AND MEDIUM PHOSPHORUS ELECTROLESS NICKEL. BY VARYING THE PERCENTAGE OF PHOSPHORUS IN THE COATING, DEPOSITS CAN BE PRODUCED THAT EXHIBIT A VARIETY OF PROPERTIES. HIGH PHOS DEPOSITS 10-13% BY WEIGHT - YIELD DEPOSITS THAT ARE NON-MAGNETIC AND HIGHLY CORROSION RESISTANT. MED PHOS DEPOSITS 6-9% BY WEIGHT - YIELD BRIGHT, HARD DEPOSITS WITH EXCELLENT WEAR RESISTANCE. THE HIGH PHOS AND MED PHOS PROCESSES ARE DESIGNED TO OPTIMIIZE DEPOSIT PROPERTIES FOR A WIDE RANGE OF ENGINEERING APPLICATIONS. TALK TO YOUR BELMONT PLATING WORKS, INC. REPRESENTATIVE ABOUT WHICH PROCESS WILL BEST SUIT YOUR CUSTOMERS NEEDS.

ELECTROLESS NICKEL

Plating Specifications Supported

SPEC ID COMPANY

B733-97 ASTM

1E2072 CATERPILLAR

MIL-C-26074 FEDERAL

10S10588 MOTOROLA

9145 KING STREET

FRANKLIN PARK, IL. 60131

PHONE: (847)678-0200

FAX: (847)678-0758

© Belmont Plating Works, Inc. 2016

AVAILABLE IN RACK AND BARREL

PROCESS

ELECTROLESS NICKEL DESCRIBES THE PLATING OF NICKEL DEPOSITS ONTO A SUBSTRATE BY CHEMICAL REDUCTION. THESE DEPOSITS MAY CONTAIN UP TO 13% PHOSPHORUS BY WEIGHT. UNLIKE ELECTROLYTIC NICKELCOATINGS, ELECTROLESS NICKEL COATINGS ARE PRODUCED ONTO CATALYTIC METALLIC SUBSTRATES WITHOUT ELECTRIC CURRENT APPLIED. BY AVOIDING MANY OF THE PROBLEMS ASSOCIATED WITH ELECTROLYTIC APPLIED COATINGS, THESE DEPOSITS PRODUCE VERY UNIFORM, HARD AND LUBRICOUS COATINGS. THE DEPOSIT UNIFORMITY ALLOWS PLATING OF VARIOUS COATING THICKNESSES ON ANY SECTION OF A PART. GROOVES, SLOTS, BLIND HOLES, THREADS AND EVEN THE INSIDE OF TUBING WILL HAVE THE SAME THICKNESS OF COATING. BELMONT PLATING WORKS, INC. OFFERS IT'S CUSTOMERS TWO OF THE MOST WIDELY USED ELECROLESS NICKELS IN THE INDUSTRY, HIGH PHOSPHORUS AND MEDIUM PHOSPHORUS ELECTROLESS NICKEL. BY VARYING THE PERCENTAGE OF PHOSPHORUS IN THE COATING, DEPOSITS CAN BE PRODUCED THAT EXHIBIT A VARIETY OF PROPERTIES. HIGH PHOS DEPOSITS 10- 13% BY WEIGHT - YIELD DEPOSITS THAT ARE NON- MAGNETIC AND HIGHLY CORROSION RESISTANT. MED PHOS DEPOSITS 6-9% BY WEIGHT - YIELD BRIGHT, HARD DEPOSITS WITH EXCELLENT WEAR RESISTANCE. THE HIGH PHOS AND MED PHOS PROCESSES ARE DESIGNED TO OPTIMIIZE DEPOSIT PROPERTIES FOR A WIDE RANGE OF ENGINEERING APPLICATIONS. TALK TO YOUR BELMONT PLATING WORKS, INC. REPRESENTATIVE ABOUT WHICH PROCESS WILL BEST SUIT YOUR CUSTOMERS NEEDS.

ELECTROLESS NICKEL